Federnfabrik Schmid, an innovative specialist in spring manufacturing, often takes part in trade fairs. The company wanted to show in a simple way how a spring in operation can be monitored thanks to new innovative technology. In order to minimize the logistics as much as possible, the whole fair device had to remain very compact and handy, even with a large spring. It had moreover to generate sufficient force to compress the spring, with a speed that could be easily observed by the eye.

- Compact design to draw the attention to the spring application

- Adjustable stroke of appr. 20 - 25 mm

- Easy maintenance

- The weight of the whole device must not be excessive

The solution

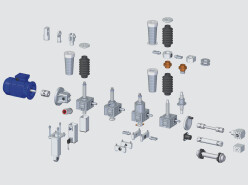

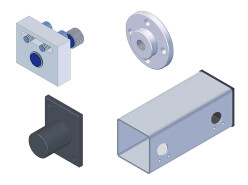

Nozag’s modular system was tailor-made to meet these requirements, and the solution was implemented completely with this system. The whole device is based on a NSE5-SL screw jack that generates the required force of up to 3 kN, has a compact design and allows a suitable slow movement. The design of the vertical screw jack also admits a variable pressure reaching 5 kN. A 500 mm long trapezoidal thread screw has been integrated to accommodate the springs and to ensure the required clearance for easy maintenance. Also the attachment parts such as e.g. a fastening flange, a protective tube and cap and limit switches used for the control have been taken from Nozag’s modular system.

- Screw jack NSE5-SL

- Standard products from stock, from the modular system

- Smooth, finely adjustable movement

- Discrete implementation thanks to a compact, light design

- Simple and low-maintenance

Shop

Shop

Any Questions?

Any Questions? Please call us

Please call us Products search

Products search

Shop

Shop