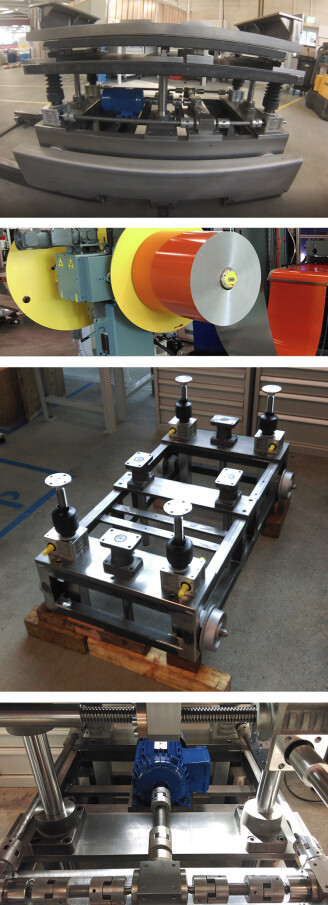

Replacing a coil (here a roll of sheet aluminum), as required in the packaging industry, requires many work steps. In addition, work safety is reduced, as the crane hook must be repositioned several times. The risk of injury is high, with important loss of time and material damage. Dominik Blatter and Jürg Brügger addressed this problem in their diploma thesis and sought engineering support from Nozag for the drive unit.

- 4-axis lifting movements

- Even and smooth movement, slow movements

- Coupling of the lift gear

- Rotation of the upper cart

- Comprehensive support and advice

The Solution

The two professionals (plant & apparatus constructor and polymechanic) designed and constructed a lift truck, taking into account a Failure Mode and Effect Analysis (FMEA). The design was also produced as a prototype and tested for functionality. The result is a lift truck that picks up the aluminum coil and automatically moves, turns and transfers it to the provided coiler at the optimum height in just a few steps. The entire lifting and lowering technology is operated by several screw jacks in combination with bevel gears and connecting shafts. All drive components were supplied by Nozag and defined in cooperation with the diploma students.

- Screw jacks for lifting/lowering movement at 4 points

- Connecting flanges as attachment parts for the screw jacks

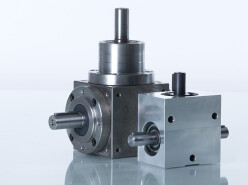

- Bevel gears with connecting shafts for uniform force transmission to the lift gear

- Engineering and calculations

Shop

Shop

Any Questions?

Any Questions? Please call us

Please call us Products search

Products search

Shop

Shop