The Challenge / The Situation

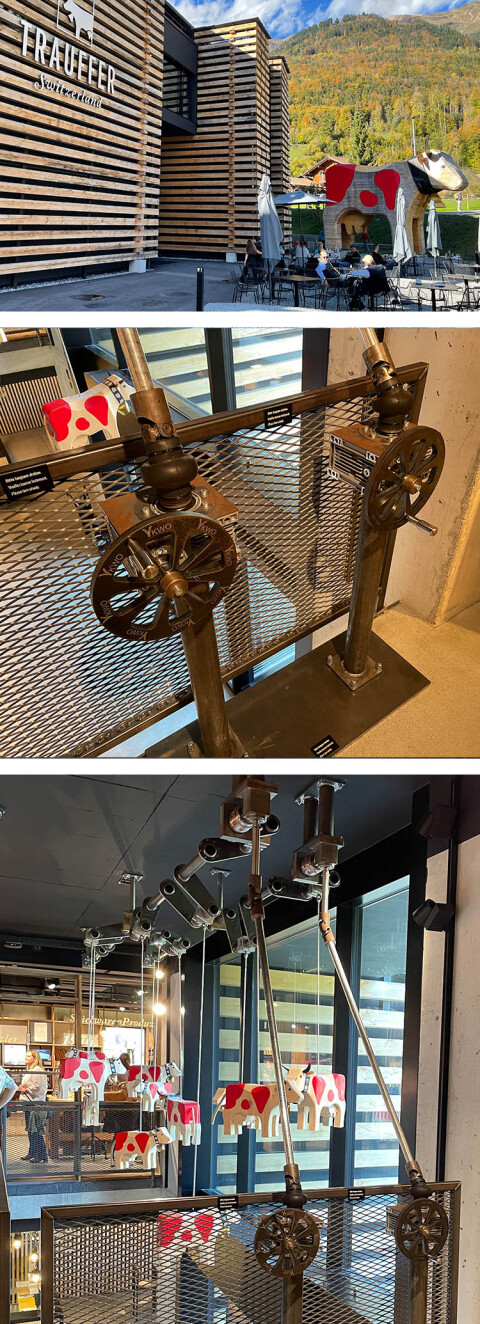

Make the Trauffer wooden cows move! This has been the first information we got from the engineering office Ingenieurbüro Bratschi. The engineers were commissioned by Grimsel Hydro to technically realize a kind of mobile in the Trauffer World of Experience. Visitors should be able to move the wooden cows up and down manually in a simple way and thus amaze the spectators. Of course, the Bratschi office had a clear idea of the project and had made accurate calculations, which we at Nozag tried to fulfill.

- Find the ideal speed

- Smooth up and down moves

- Transmit the drive movement over distances

- Simple, low-maintenance and safe

The Solution

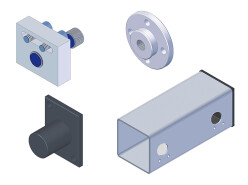

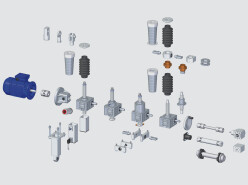

The solution was quickly found thanks to the good engineering knowledge of the customer and his clear specifications. Once more, Nozag’s modular system for system drives showed all its advantages. A CHM series worm gear driven by a hand crank was used at the point of contact with the visitors. Easy to actuate, perfect for fine movements and very robust. The drive movement is transmitted upwards via steel shafts, made vertical by a universal joint to allow a bevel gear with a 1:1 ratio to transmit the driving force horizontally. Bevel gears are ideal for such applications, as they are silent, maintenance-free, and compact. Of course, both drives are available in various versions.

- CHM series worm gear

- RM bevel gear

- Standard products from stock, or modular system

- All of them are silent, maintenance-free and designed for manual operation

«Thanks to Nozag’s wide standard range and modular system, we quickly found the right components.»

Frank Bratschi, Manager/Owner, Ingenieurbüro Bratschi

Products / Detailed information

Thanks to its wide products range and variety, Nozag’s modular system is very helpful to solve specific individual situations. In addition, we can also deliver quantities of several parts directly from stock. Come and have a look or allow us to advise you for the optimization of drive solutions.

Shop

Shop

Any Questions?

Any Questions? Please call us

Please call us Products search

Products search

Shop

Shop